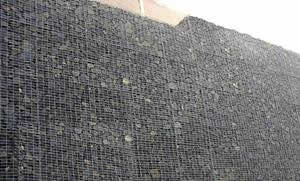

Gabions boxes are wire containers made of hexagonal wire netting. Wire diameter varies with the hexagonal nettings. For hexagonal wire netting with no pvc coating, the wire diameter ranges from 2.0mm to 4.0mm. For those PVC coated hexagonal wire netting, the outside diameter ranges from 3.0mm to 4.0mm. The wire of the outside frame edge is one wire gauge thicker than the wire used for hexagonal wire netting.

Features:

Economic. Just fill the stone into the gabions and seal it.

Simple installation. No special technology needed.

Weather proof under natural destroy, corrosion resistant.

No collapse even under big scope of deforming.

Sludge in the stones is good for plant growing. Mixed to form a integrity with the natural environment.

Good permeation can prevent the damage by hydrostatic.

Less transport freight. It can be folded together for transport and further installation.

|

|

|

|

Gabion boxes applications:

Control and guide of water or flood

Flood bank or guiding bank

Preventing of rock breaking

Water and soil protection

Bridge protection

Strengthening structure of soil

Protection engineering of seaside area.

Opening |

Wire Diameter(Metal Wire) (mm) |

Wire Diameter (PVC Coate)/ Inner/Outside(mm) |

Strands |

60X80 |

φ2.0-2.8 |

φ2.0/3.0-2.5/3.5 |

3 |

80X100 |

φ2.0-3.2 |

φ2.0/3.0-2.8/3.8 |

3 |

80X120 |

φ2.0-3.2 |

φ2.0/3.0-2.8/3.8 |

3 |

100X120 |

φ2.0-3.4 |

φ2.0/3.0-2.8/3.8 |

3 |

100X150 |

φ2.0-3.4 |

φ2.0/3.0-2.8/3.8 |

3 |

120X150 |

φ2.0-4.0 |

φ2.0/3.0-3.0/4.0 |

3 |

Gabion Sack,Sack Gabion

Gabion Sacks are cylindrical units which are made of doubel twisted steel woven wire mesh panel 6*8,8*10,10*12,12*15cm according to ASTM A 975 and EN10223.Gabion Sacks are filled with stone at the site to form flexible and durable structures to be used in river training and emergency works.Sack gabions are supplied with reinforcing wires to be inserted during the manufacturing process to facolitate closing during installation.the wire used in gabion sacks is heavily zinc coated soft temper steel.

Sackgabion |

||

Lenght(m) |

Diameter(m) |

volume(m3) |

1.8 |

0.6 |

0.54 |

2.7 |

0.6 |

0.80 |

1.8 |

0.9 |

1.2 |

2.7 |

0.9 |

1.80 |

|

|

Top Welded wire Gabion are made by one of the nation��s leading manufacturers of welded wire mesh. Each Gabion is constructed of rugged hight tensile wire which is coated with a thick, cor-rosion-resistant layer of zinc. The wire is also available with a tough,durable PVC coating. The jality materials results in a longer,Gabion life. Top welded wire supplied from stock in a complete Custom sizes to fit unique site con-ailable on special order.

Field installation is quick and easy. In fact, installation time can be as much as 40% less than required by hex type Gabions. With diaphragms and stiffeners installed,the Gabion may be filled with standard loading equipment.After filling the Gabion, a lid is placed on top and secured with spiral binders,lacing wire or ��C�� rings.

Unlike hexagonal units, Top welded wire Gabion hold their shape better �C they don��t bulge out when filled .They are easy to handle,which means more work,less labor and highter productivity an the job.

|

|

The Reno mattress is a structure made of hexagonal double twisted wire mesh. Reno mattresses are filled with stones at the project site to form flexible and permeable, monolithic structures such as river bank protection and channel linings for erosion control. The steel wire used to manufacture the mattress is heavily zinc-coated soft temper steel. The standard combinations of mesh is shown in Table. In order to reinforce the structure, all mesh panel edges are selvedged with a wire having a greater diameter. Reno mattresses are divided into uniformly partitioned cells by internal diaphragms.

Table of sizes for Reno mattresses��

Length(m) |

Width(m) |

Height(m) |

Mesh type(m) |

3m |

2m |

0.15-0.20-0.25 |

5x7 |

4m |

2m |

0.15-0.20-0.25 |

5x7 |

5m |

2m |

0.15-0.20-0.25 |

5x7 |

6m |

2m |

0.15-0.20-0.25 |

5x7 |

3m |

2m |

0.17-0.23-0.30 |

6x8 |

4m |

2m |

0.17-0.23-0.30 |

6x8 |

5m |

2m |

0.17-0.23-0.30 |

6x8 |

6m |

2m |

0.17-0.23-0.30 |

6x8 |

All sizes and dimensions are nominal. Tolerances of �� 3% of the width, length, and ��2.5 cm of the height shall be permitted

Reno Mattress

Reno mattresses are used for river bank and scour protection, channel linings for erosion control, and embankment stability. They are filled with rock at the project site to form flexible, permeable and monolithic structures to promote rapid growth of natural vegetation. All the physical and mechanical properties of Haifeng Reno mattresses meet or exceed the requirements of ASTM A975-97.

The base section of the Reno mattress is divided into compartments and filled with stones at the project site. With lids secured, Reno mattresses form flexible, permeable and monolithic structures.

Flexibility

The woven mesh system has the capability of withstanding unexpected and/or localized stresses due to ground settlements and scour by deflection while maintaining its structural integrity.

Permeability

The stone fill allows the water to seep through the structure while retaining the soil, therefore no additional drainage is required to relieve the hydrostatic pressures.

Coating

Reno mattresses are available with different levels of coating protection for durability in a wide range of environments and climatic conditions. Reno mattresses are manufactured from coated wire offering about three time greater protection than zinc coated wire mattresses. Where Reno mattresses come in contact with more aggressive environments, an additional polymer protective coating is applied over the Haifeng coating to maximise the level of protection.

Environmental Friendly

Reno mattresses are environmentally friendly products. The blending of Reno mattress structures into the environment is rapid and pleasing. The voids in the rockfill become progressively filled with silt, promoting vegetation growth which is essential to the preservation and maintenance of the ecological balance of the surrounding environment.

Cost Effective, Easy to Build

Reno mattress construction does not require skilled labor because they are very easy to build. Standard construction equipment can be used. Structures can be built in stages, if necessary, and baskets can be prefilled and launched to enable the installation under water. Site assistance is available from any Haifeng area office.